What is a Waterproof Distribution Box and Why You Need One for Your Projects

In today’s rapidly evolving construction and electrical sectors, the importance of effective power distribution cannot be overstated. A

Waterproof Distribution Box is an essential component for any outdoor project, as it safeguards electrical connections

from moisture, dust, and other environmental elements. According to a report by MarketsandMarkets, the global electrical distribution equipment market size is expected to reach

USD 200 billion by 2027, driven by growing infrastructure development and the need for reliable energy solutions. This highlights the critical

role that equipment like waterproof distribution boxes play in ensuring safety and reliability in electrical installations.

Projects ranging from commercial buildings to residential developments increasingly require robust protection against weather-related risks,

making the investment in a high-quality waterproof distribution box not only a practical choice but a necessary one for managing both current and future electrical demands.

Understanding Waterproof Distribution Boxes: Key Features and Benefits

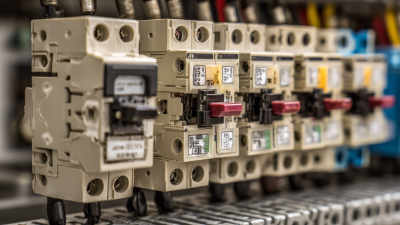

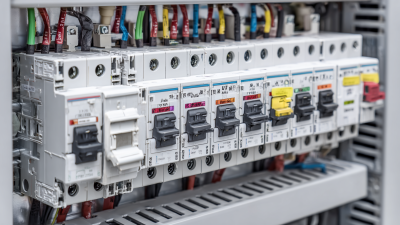

Waterproof distribution boxes are essential components in various electrical projects, especially in environments exposed to moisture and harsh conditions. These specialized enclosures provide robust protection for electrical connections and equipment, ensuring safety and longevity. One of the key features of waterproof distribution boxes is their high IP (Ingress Protection) rating, which indicates their ability to resist water and dust infiltration. This rating is crucial for projects in outdoor settings, such as landscape lighting or garden irrigation systems, where exposure to the elements is inevitable.

In addition to their protective capabilities, waterproof distribution boxes offer several benefits that enhance project efficiency. They come equipped with user-friendly layouts and ample space for wiring and connections, simplifying installation processes. Furthermore, these boxes often include built-in cable management solutions, helping to organize wires and prevent tangling or damage. The durability and resilience of these enclosures not only protect your investments but also reduce maintenance costs over time, making them an invaluable addition to your project toolkit.

Industry Standards: Waterproof Ratings and Their Importance in Distribution Boxes

When selecting a waterproof distribution box, understanding industry standards and waterproof ratings is crucial. The Ingress Protection (IP) rating system, established by the International Electrotechnical Commission (IEC), categorizes devices based on their protection against dust and moisture. For instance, an IP65 rating signifies that the distribution box is dust-tight and can withstand low-pressure water jets, making it suitable for outdoor projects exposed to varying weather conditions. According to a recent report by MarketsandMarkets, the global waterproof electrical enclosures market is projected to reach $3.88 billion by 2027, highlighting a growing recognition of the importance of protective ratings in preventing electrical failures and enhancing safety.

Furthermore, the National Electrical Manufacturers Association (NEMA) plays a vital role in defining standards for waterproof enclosures, providing ratings that range from NEMA 1 (for indoor use) to NEMA 6 (for submersion). Choosing a distribution box that meets these standards not only protects electrical components but also ensures compliance with safety regulations and extends the lifespan of equipment. As industries increasingly rely on automation and technology, investing in high-quality waterproof distribution boxes is becoming a necessity to mitigate risks associated with adverse environmental conditions.

Essential Applications: When and Where You Should Use a Waterproof Distribution Box

When considering outdoor electrical projects, the importance of a waterproof distribution box cannot be overstated. These boxes are designed to protect electrical connections from moisture and adverse weather conditions, ensuring safety and longevity. Common applications include garden lighting, outdoor outlets, and security systems, which all require robust protection against the elements. According to a recent report, nearly 30% of outdoor electrical failures are attributed to weather-related issues. Using a waterproof distribution box can significantly reduce this risk, providing peace of mind for any outdoor installation.

Understanding the National Electrical Code (NEC) is critical when using a waterproof distribution box for outdoor projects. The NEC outlines essential safety standards that must be followed to ensure compliance and prevent electrical hazards. For instance, the NEC emphasizes the importance of using weatherproof enclosures in areas prone to moisture, reinforcing the need for a waterproof solution. With top-rated boxes in 2023 showcasing enhanced weather resistance and durability, choosing the right distribution box can make all the difference in the success of your outdoor electrical projects.

Comparative Analysis: Waterproof vs. Standard Distribution Boxes in Project Efficiency

In the realm of electrical installations, the choice between waterproof and standard distribution boxes can significantly impact project efficiency. According to a report by the International Electrotechnical Commission, approximately 30% of electrical failures in outdoor environments can be attributed to moisture damage, highlighting the necessity of waterproof solutions in non-controlled settings. Waterproof distribution boxes are engineered to safeguard electrical connections from environmental factors, which not only prolongs the lifespan of the equipment but also minimizes maintenance costs.

Comparative analysis indicates that while standard distribution boxes can suffice in sheltered areas, they fall short in challenging conditions such as construction sites or outdoor installations. The National Association of Electrical Distributors states that projects utilizing waterproof distribution boxes can reduce system outages by up to 40%, leading to enhanced operational stability and cost savings over time. This efficiency stems from reduced downtime and fewer repairs, ultimately translating to smoother project execution and enhanced reliability in critical applications.

Maintenance Tips: Ensuring Longevity for Your Waterproof Distribution Boxes in Harsh Conditions

When utilizing waterproof distribution boxes, maintenance is key to ensuring their longevity, especially in harsh environmental conditions. Data from the Electrical Safety Foundation International (ESFI) indicates that improper installation and maintenance account for nearly 25% of all electrical failures. To avoid such pitfalls, regular inspections and adherence to best practices are essential.

Tip 1: Regularly check seals and gaskets for signs of wear. The integrity of these components is crucial in preventing water ingress, which can lead to electrical malfunctions. A report by the International Electrotechnical Commission (IEC) highlights that even minor breaches can compromise the safety and functionality of electrical systems.

Tip 2: Clean the distribution box periodically to remove dirt and debris. Accumulation of contaminants can lead to overheating and other electrical issues. According to the National Fire Protection Association (NFPA), electrical equipment maintenance can reduce failure rates by up to 20%, making a clean environment critical for operational reliability.

Tip 3: Maintain a consistent temperature around the distribution box. Extreme temperature fluctuations can cause materials to expand and contract, potentially leading to damage. The Institute of Electrical and Electronics Engineers (IEEE) suggests that maintaining optimal operating temperatures can enhance the lifespan of electrical components significantly.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor