Top Strategies for Maximizing Efficiency with Distribution Boxes

In today's fast-paced logistics environment, maximizing efficiency in distribution processes is crucial for maintaining competitiveness and profitability. According to a report by Supply Chain Dive, companies that optimize their distribution strategies can enhance their operational efficiency by up to 30%. A pivotal component in this optimization is the Distribution Box, which serves as a centralized hub for managing goods and information flow.

By effectively utilizing Distribution Boxes, businesses can streamline inventory management, reduce delivery times, and minimize operational costs. Leveraging advanced technologies and best practices associated with Distribution Boxes can significantly transform the distribution landscape, supporting firms in achieving their efficiency goals while ensuring customer satisfaction and retention. Understanding the critical strategies for utilizing these vital assets can set organizations on a path to sustained success in an ever-evolving market.

By effectively utilizing Distribution Boxes, businesses can streamline inventory management, reduce delivery times, and minimize operational costs. Leveraging advanced technologies and best practices associated with Distribution Boxes can significantly transform the distribution landscape, supporting firms in achieving their efficiency goals while ensuring customer satisfaction and retention. Understanding the critical strategies for utilizing these vital assets can set organizations on a path to sustained success in an ever-evolving market.

Best Practices for Selecting the Right Distribution Box for Your Operations

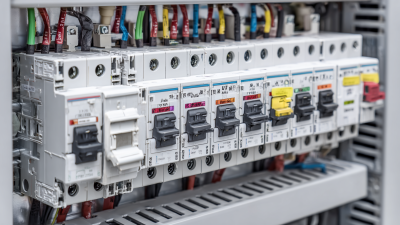

Selecting the right distribution box is crucial for optimizing operational efficiency in various industries. According to a recent report by Future Market Insights, the global market for electrical distribution boxes is projected to reach USD 7 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.5%. This growth highlights the increasing importance of reliable electrical distribution systems in enhancing productivity and reducing downtime.

To choose the right distribution box, first consider the specific requirements of your operations, such as load capacity and environmental conditions. A study by the Electrical Wiring and Cable Institute notes that improper selection can lead to overheating, leading to a 30% reduction in electrical equipment lifespan. It's advised to consult the latest industry standards, like those set by the National Electrical Manufacturers Association (NEMA), to ensure compliance and safety. Additionally, investing in boxes with modular design features can facilitate easier upgrades and maintenance, thereby improving long-term efficiency and adaptability to changing operational needs.

Maximizing Space Utilization in Distribution Centers with Effective Layout Strategies

Efficient space utilization in distribution centers is critical for maximizing productivity and reducing costs. According to a report by the Warehousing Education and Research Council (WERC), effective layout strategies can improve space utilization by up to 30%. This translates into significant cost savings, especially in sectors where real estate expenses are high. Implementing a well-organized racking system, for example, can facilitate better stock management and quicker access to goods, ultimately enhancing order fulfillment times.

One key strategy to maximize space utilization involves optimizing inventory layouts based on product velocity. A study published by the Council of Supply Chain Management Professionals (CSCMP) shows that strategically placing high-demand items closer to shipping areas can decrease picking times by as much as 25%. Furthermore, adopting innovative technologies such as automated storage and retrieval systems (AS/RS) can also maximize vertical space and reduce the footprint of distribution operations. Investing in these layout strategies not only leads to improved efficiency but also elevates overall operational performance in distribution centers.

Top Strategies for Maximizing Efficiency with Distribution Boxes

This chart illustrates the effectiveness of different layout strategies for maximizing space utilization in distribution centers. The data shows the percentage improvement in efficiency associated with various strategies implemented.

Leveraging Technology: Automation Solutions for Enhanced Distribution Box Efficiency

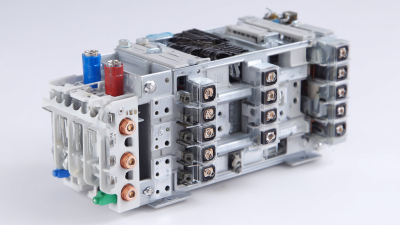

In today's fast-paced distribution environment, leveraging technology through automation solutions has become essential for enhancing the efficiency of distribution boxes. Automation not only streamlines operations but also reduces human error and increases throughput. By integrating smart technology, such as IoT-enabled sensors and automated inventory management systems, businesses can monitor the performance of their distribution boxes in real-time. This capability allows for proactive maintenance and adjustments, ensuring that systems operate at peak efficiency.

Moreover, implementing software that utilizes machine learning algorithms can significantly optimize the scheduling and routing of distribution tasks. These intelligent systems analyze historical data to predict peak times, allowing for better resource allocation and reduced operational costs. By automating repetitive tasks and providing real-time insights, companies can free up valuable human resources to focus on strategic initiatives, ultimately driving growth and innovation in their distribution processes.

Analyzing Industry Data: Impact of Distribution Box Optimization on Supply Chain Performance

In the current supply chain landscape, optimizing distribution boxes can lead to significant improvements in overall performance. Analyzing industry data reveals that the effective use of distribution boxes enhances not only the efficiency of goods movement but also reduces operational costs. By streamlining the processes involved in the distribution phase, companies can achieve quicker turnaround times and improve their inventory management. The strategic design of these boxes allows for better space utilization, which minimizes waste and essentially maximizes throughput.

In the current supply chain landscape, optimizing distribution boxes can lead to significant improvements in overall performance. Analyzing industry data reveals that the effective use of distribution boxes enhances not only the efficiency of goods movement but also reduces operational costs. By streamlining the processes involved in the distribution phase, companies can achieve quicker turnaround times and improve their inventory management. The strategic design of these boxes allows for better space utilization, which minimizes waste and essentially maximizes throughput.

Moreover, insights gained from analyzing performance metrics show a direct correlation between distribution box optimization and customer satisfaction. When distribution boxes are tailored to meet specific needs, they enable smoother handling and sorting of products, which ultimately leads to faster delivery times. This responsiveness is crucial in today’s market, where consumer expectations are continuously rising. Therefore, organizations that harness data analysis to refine their distribution box strategies position themselves to not only boost efficiency but significantly enhance their competitive advantage in the supply chain arena.

Sustainability in Distribution: Eco-Friendly Materials and Practices for Distribution Boxes

In an era where sustainability is paramount, the use of eco-friendly materials in the manufacturing of distribution boxes is a crucial step towards reducing environmental impact. Companies are increasingly adopting materials such as recycled plastics and biodegradable options that not only minimize carbon footprints but also enhance the durability and lifespan of these boxes. Utilizing such sustainable materials demonstrates a commitment to environmental stewardship while still meeting the rigorous demands of modern distribution needs.

Moreover, implementing eco-friendly practices within the distribution process can further maximize efficiency. For instance, optimizing packaging to reduce waste, consolidating shipments to minimize fuel consumption, and utilizing renewable energy sources for transportation are all effective strategies. By fostering a culture of sustainability, organizations not only improve their operational efficiency but also appeal to a growing segment of eco-conscious consumers. Adopting these practices not only contributes to a healthier planet but also positions businesses as leaders in corporate responsibility within the industry.

Top Strategies for Maximizing Efficiency with Distribution Boxes

| Strategy |

Description |

Eco-Friendly Material |

Benefits |

Implementation Time |

| Modular Design |

Utilization of interchangeable components for better customization. |

Recycled plastic |

Increases versatility and reduces waste. |

2-3 weeks |

| Smart Technology Integration |

Using IoT for real-time monitoring and management. |

Biodegradable sensors |

Enhances efficiency through data analysis. |

1-2 months |

| Optimized Routing |

Algorithm-driven route planning for deliveries. |

Recycled metals |

Reduces operational costs and lowers carbon emissions. |

2 weeks |

| Eco-Friendly Packaging |

Utilizing sustainable materials for packaging distribution boxes. |

Compostable cardboard |

Minimizes waste and improves brand image. |

1 month |

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor By effectively utilizing Distribution Boxes, businesses can streamline inventory management, reduce delivery times, and minimize operational costs. Leveraging advanced technologies and best practices associated with Distribution Boxes can significantly transform the distribution landscape, supporting firms in achieving their efficiency goals while ensuring customer satisfaction and retention. Understanding the critical strategies for utilizing these vital assets can set organizations on a path to sustained success in an ever-evolving market.

By effectively utilizing Distribution Boxes, businesses can streamline inventory management, reduce delivery times, and minimize operational costs. Leveraging advanced technologies and best practices associated with Distribution Boxes can significantly transform the distribution landscape, supporting firms in achieving their efficiency goals while ensuring customer satisfaction and retention. Understanding the critical strategies for utilizing these vital assets can set organizations on a path to sustained success in an ever-evolving market.

In the current supply chain landscape, optimizing distribution boxes can lead to significant improvements in overall performance. Analyzing industry data reveals that the effective use of distribution boxes enhances not only the efficiency of goods movement but also reduces operational costs. By streamlining the processes involved in the distribution phase, companies can achieve quicker turnaround times and improve their inventory management. The strategic design of these boxes allows for better space utilization, which minimizes waste and essentially maximizes throughput.

In the current supply chain landscape, optimizing distribution boxes can lead to significant improvements in overall performance. Analyzing industry data reveals that the effective use of distribution boxes enhances not only the efficiency of goods movement but also reduces operational costs. By streamlining the processes involved in the distribution phase, companies can achieve quicker turnaround times and improve their inventory management. The strategic design of these boxes allows for better space utilization, which minimizes waste and essentially maximizes throughput.