7 Reasons Why Ac Contactors Are Essential for Electrical Efficiency in Modern Factories

In the rapidly evolving landscape of modern manufacturing, maintaining electrical efficiency is paramount for operational excellence.

AC contactors play a crucial role in achieving this efficiency, as highlighted by industry reports suggesting that up to 30% of energy consumption in factories arises from inefficient electrical systems.

According to a study by the International Energy Agency, the implementation of advanced electrical components, like AC contactors, can reduce overall energy usage by significant margins, sometimes exceeding 20%.

These devices not only enhance the reliability of motor control systems but also contribute to lower maintenance costs and improved safety standards.

As industries seek to minimize their carbon footprint and optimize production processes, understanding the multifaceted benefits of AC contactors is essential for anyone aiming to improve their factory's electrical efficiency.

Importance of AC Contactors in Enhancing Electrical Efficiency

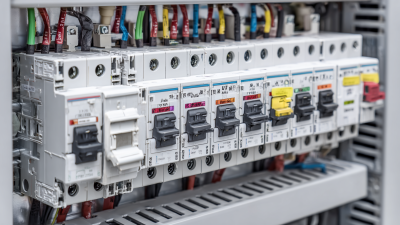

AC contactors play a critical role in enhancing electrical efficiency in modern factories. These devices function as electromechanical switches that control the flow of electricity to large equipment and machinery. By efficiently managing the power supply, AC contactors help minimize energy losses, optimizing the overall electrical load in industrial settings. This efficiency is essential not only for reducing operational costs but also for ensuring the longevity of equipment, as they prevent overheating and potential damage caused by overloads.

Moreover, the importance of AC contactors extends beyond just energy savings. They contribute significantly to safety protocols within factories by allowing for safe and reliable control of high-voltage equipment. When integrated with automated systems, contactors enable smoother operations, reducing downtime and increasing productivity. Additionally, their ability to handle frequent switching operations makes them indispensable in applications where machines need to start and stop regularly. In this way, AC contactors emerge as indispensable components in the quest for sustainable and efficient manufacturing processes.

7 Reasons Why AC Contactors Are Essential for Electrical Efficiency in Modern Factories

| Reason |

Description |

Impact on Efficiency |

| 1. Reliable Operation |

AC contactors provide a dependable mechanism for starting and stopping motors. |

Reduces downtime, allowing for increased production. |

| 2. Energy Savings |

They optimize energy consumption by ensuring proper load management. |

Lower operating costs through reduced energy waste. |

| 3. Enhanced Safety |

Contactors include safety features that protect against overload and short-circuits. |

Minimizes risk of accidents, promoting a safer work environment. |

| 4. Automation Compatibility |

They work seamlessly with automated systems for greater efficiency. |

Improves workflow and reduces manual intervention. |

| 5. Durable Performance |

Constructed to withstand harsh industrial environments. |

Longer lifespan reduces replacement frequency. |

| 6. Easy Maintenance |

Design allows for quick inspections and maintenance. |

Saves time and labor costs in maintenance activities. |

| 7. Versatile Applications |

Suitable for a variety of industrial machines and processes. |

Flexibility in setup enhances operational efficiency across different areas. |

Key Features of AC Contactors That Boost Operational Performance

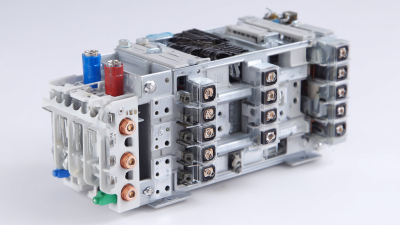

AC contactors play a crucial role in enhancing electrical efficiency in modern factories, primarily due to their key features designed to optimize operational performance. One of the most significant attributes of AC contactors is their ability to handle high-frequency switching. This capability allows for rapid activation and deactivation of electrical loads, reducing energy wastage and improving system responsiveness. The robust construction of modern AC contactors ensures they can withstand the demands of heavy-duty applications, providing reliable operation even under challenging conditions.

AC contactors play a crucial role in enhancing electrical efficiency in modern factories, primarily due to their key features designed to optimize operational performance. One of the most significant attributes of AC contactors is their ability to handle high-frequency switching. This capability allows for rapid activation and deactivation of electrical loads, reducing energy wastage and improving system responsiveness. The robust construction of modern AC contactors ensures they can withstand the demands of heavy-duty applications, providing reliable operation even under challenging conditions.

Another important feature is their integration with control systems, enabling automation and remote management of machinery. This connectivity not only streamlines operations but also minimizes downtime, as issues can be diagnosed and addressed quickly. Additionally, many AC contactors come equipped with overload protection and advanced monitoring capabilities, allowing for real-time performance insights and preventative maintenance. By adopting AC contactors with these key features, factories can significantly boost their operational efficiency, leading to better resource management and enhanced productivity.

How AC Contactors Contribute to Energy Cost Savings

In modern factories, AC contactors play a pivotal role in enhancing energy efficiency and reducing operational costs. These electromechanical devices are essential for controlling the power supply to machinery, allowing for precise management of power consumption. According to a report from the International Energy Agency, optimizing industrial energy use can reduce total energy costs by up to 20%. By integrating AC contactors, manufacturers not only streamline the power management of heavy equipment but also improve the overall energy efficiency of their operations.

Moreover, AC contactors can significantly contribute to energy cost savings through improved switching capabilities. When paired with motor starters and sensors, they ensure that machinery runs only when needed, minimizing idle energy consumption. A study by the U.S. Department of Energy indicates that intelligent motor controls, which often employ AC contactors, can result in energy savings of 30% or more in variable load applications. This capability to dynamically adjust energy use reinforces the importance of AC contactors in modern factory settings, firmly establishing them as a key component in achieving both efficiency and financial savings.

Energy Cost Savings from AC Contactors

This bar chart illustrates the annual energy costs for a factory before and after the installation of AC contactors, showing a significant reduction in costs due to enhanced electrical efficiency.

Safety Benefits of Utilizing AC Contactors in Industrial Settings

In modern industrial environments, safety is paramount, and the utilization of AC contactors plays a crucial role in achieving this. AC contactors are designed to switch electrical circuits on and off, helping to control large currents safely — a necessity when managing the inherent risks associated with high-voltage systems. By employing these devices, factories can ensure that operational hazards are minimized, thereby safeguarding both equipment and personnel.

In modern industrial environments, safety is paramount, and the utilization of AC contactors plays a crucial role in achieving this. AC contactors are designed to switch electrical circuits on and off, helping to control large currents safely — a necessity when managing the inherent risks associated with high-voltage systems. By employing these devices, factories can ensure that operational hazards are minimized, thereby safeguarding both equipment and personnel.

Furthermore, advanced solutions like vacuum contactors offer enhanced safety features for medium-voltage power distribution systems. These contactors not only facilitate the switching of currents but also provide end-to-end protection throughout the system's operation. Their ability to interrupt current flow safely under load conditions helps prevent electrical faults and potential damage to machinery. This reliability fosters a safer work environment, allowing industries to maintain productivity without compromising on worker safety or equipment integrity. Embracing AC contactors is therefore essential for any modern factory seeking to elevate its operational efficiency and safety standards.

Maintenance Tips for Ensuring Optimal Performance of AC Contactors

To ensure optimal performance of AC contactors in modern factories, regular maintenance is key. One of the most essential maintenance tips is to perform routine inspections. During these inspections, look for signs of wear and tear, such as burnt contacts or loosened connections. Catching these issues early can prevent more significant problems down the line and ensure that the contactors operate efficiently.

Another crucial aspect of maintenance is ensuring that the contactors are kept clean and free from dust and debris. Accumulated dirt can impede performance and lead to overheating. Using compressed air to blow out any dust and performing a thorough cleaning regularly can go a long way in maintaining their effectiveness. Furthermore, checking the capacity and functionality of the associated electrical components, such as relays and overload protectors, will contribute to the overall efficiency of the entire system. By adopting these maintenance practices, factories can maximize the lifespan and reliability of their AC contactors, ultimately driving enhanced electrical efficiency.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor

AC contactors play a crucial role in enhancing electrical efficiency in modern factories, primarily due to their key features designed to optimize operational performance. One of the most significant attributes of AC contactors is their ability to handle high-frequency switching. This capability allows for rapid activation and deactivation of electrical loads, reducing energy wastage and improving system responsiveness. The robust construction of modern AC contactors ensures they can withstand the demands of heavy-duty applications, providing reliable operation even under challenging conditions.

AC contactors play a crucial role in enhancing electrical efficiency in modern factories, primarily due to their key features designed to optimize operational performance. One of the most significant attributes of AC contactors is their ability to handle high-frequency switching. This capability allows for rapid activation and deactivation of electrical loads, reducing energy wastage and improving system responsiveness. The robust construction of modern AC contactors ensures they can withstand the demands of heavy-duty applications, providing reliable operation even under challenging conditions.

In modern industrial environments,

In modern industrial environments,