Common Challenges Encountered with Air Conditioner Condensate Pumps and Their Solutions

Air Conditioner Condensate Pumps play a critical role in the efficient operation of HVAC systems, especially in the removal of condensate produced by air conditioning units. According to the U.S. Department of Energy, effective moisture control is essential not only for maintaining indoor air quality but also for enhancing energy efficiency, as improper management of condensate can lead to mold growth and system inefficiency. However, these pumps often face challenges such as clogs, mechanical failures, and improper installation, which can compromise their performance and lead to costly repairs. Industry reports highlight that nearly 30% of HVAC system failures are related to condensate pump issues, making it imperative for homeowners and service professionals to understand these challenges and their solutions. This blog will explore the common problems associated with Air Conditioner Condensate Pumps and provide practical solutions to ensure optimal functioning and prolong the life of HVAC systems.

Common Issues with Air Conditioner Condensate Pumps: A Comparative Overview

When dealing with air conditioner condensate pumps, several common issues can arise that may hinder their performance. One of the most frequent problems is clogging due to dirt and debris accumulation within the pump or drain lines. This can lead to inefficient operation and even system failure. Regular maintenance, including cleaning the pump and drain lines, is crucial to ensure optimal functionality and prevent unexpected breakdowns.

Another challenge is the pump's inability to activate when there is condensate buildup. This can often be traced back to electrical issues or a malfunctioning float switch. To mitigate this risk, homeowners should periodically check the electrical connections and ensure that the float switch is functioning properly. Professional servicing is recommended if you notice persistent issues, as these components are vital for the pump's operation.

Tip: Install a secondary backup pump or alarm system to alert you in case of a failure. This can prevent extensive water damage in your home by providing an additional layer of protection. Furthermore, consider using a condensate pump that features a built-in safety switch to prevent overflow, ensuring that your air conditioning system remains efficient and reliable throughout its use.

Understanding the Design Differences in Condensate Pumps

Air conditioner condensate pumps play a critical role in managing excess moisture generated by HVAC systems. Understanding the design differences among these pumps can aid in selecting the right one for specific applications. For instance, there are two primary types of condensate pumps: primary and secondary. Primary pumps are designed to handle direct water removal from the AC unit, while secondary pumps are often used as a backup system to prevent overflow in case the primary pump fails. According to a recent study by the Air-Conditioning, Heating, and Refrigeration Institute (AHRI), approximately 30% of HVAC system failures are related to drainage issues, making the correct selection of condensate pumps essential.

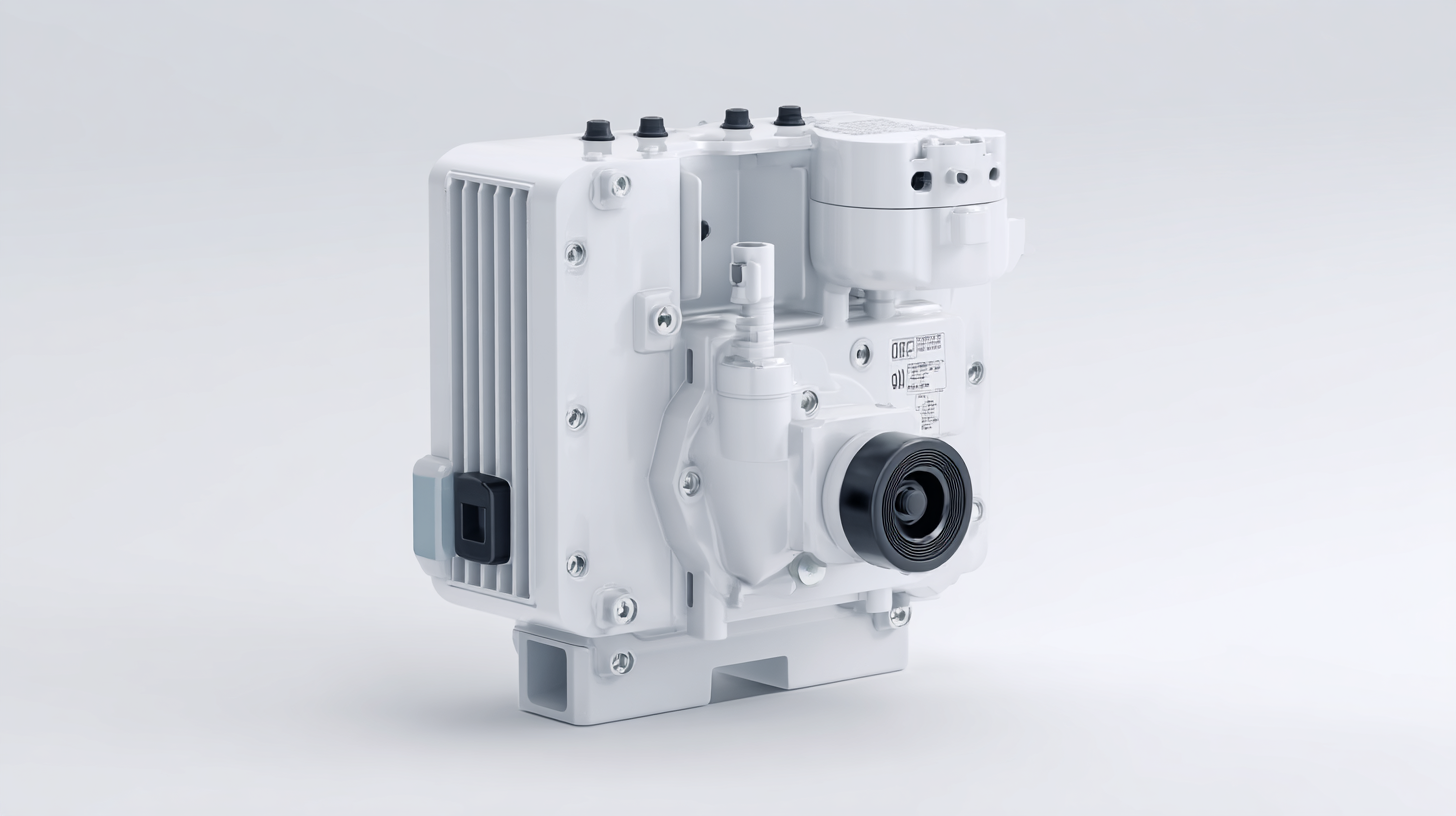

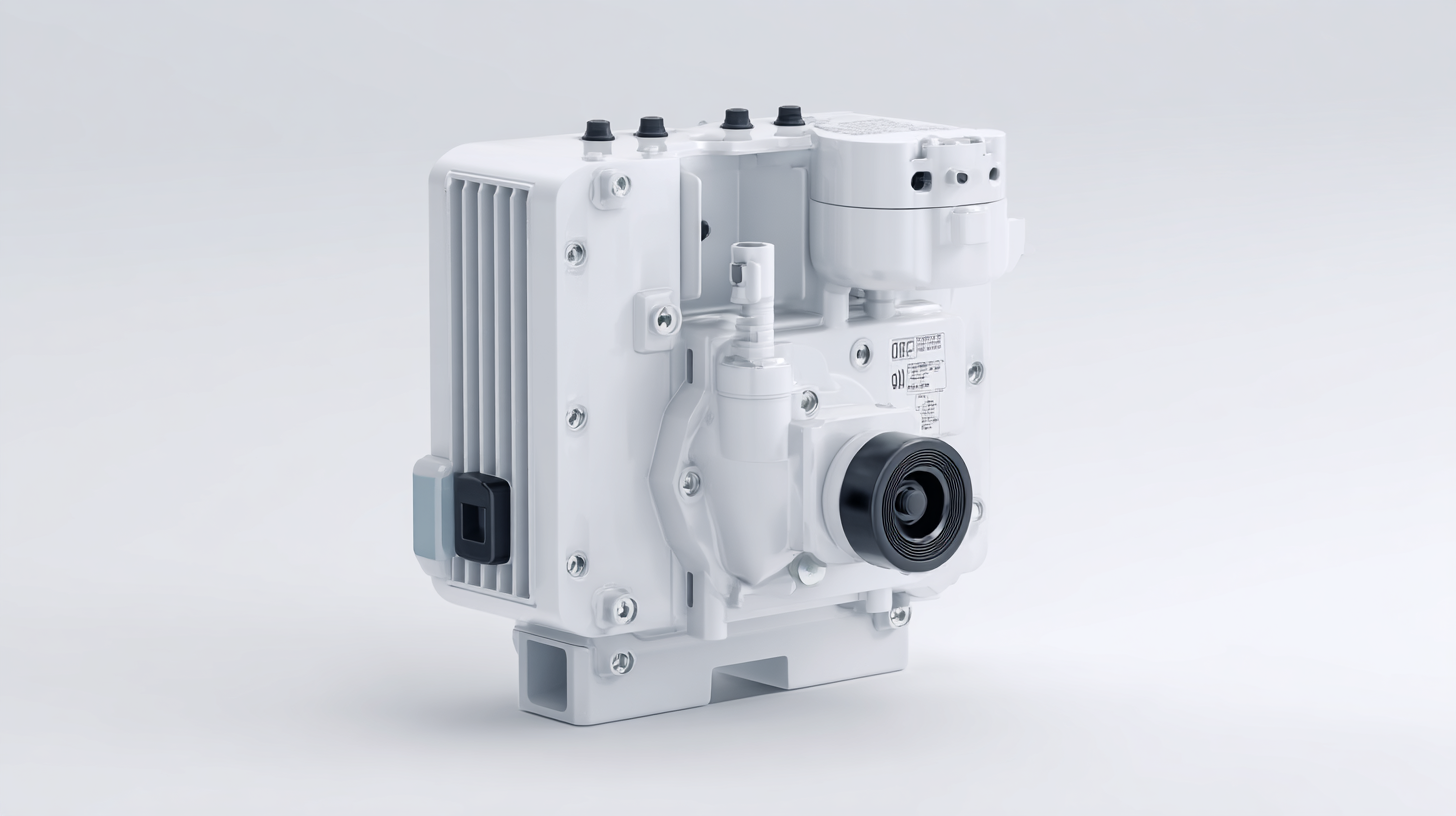

Design characteristics such as capacity, float switch mechanisms, and material composition are vital in determining the efficiency and longevity of condensate pumps. A report from the U.S. Department of Energy highlights that pumps with higher capacities typically have more robust motors, which can significantly reduce the likelihood of clogging and hydraulic failure. Furthermore, pumps constructed from corrosion-resistant materials are recommended, particularly in environments prone to chemical exposure. By understanding these design differences, HVAC professionals can mitigate common challenges associated with condensate pumps, ensuring optimal performance and system reliability.

Performance Comparison: Standard vs. High-Efficiency Condensate Pumps

When comparing standard and high-efficiency condensate pumps, performance is a critical factor that can significantly impact air conditioning systems. Standard condensate pumps generally fulfill basic operational requirements; however, they often fall short in terms of energy efficiency and reliability, particularly under high-demand conditions. Recent advancements in technology highlight the potential of high-efficiency condensate pumps, which leverage innovative designs to optimize performance.

These pumps not only improve energy usage but also enhance system longevity, addressing common issues related to condensate buildup and pump failure.

Innovations in HVAC systems are reflecting a broader trend towards energy-efficient construction and renewable energy applications. For instance, the integration of low-global warming potential refrigerants and advanced heat exchange technologies demonstrates a shift in focus towards sustainability. As the demand for air conditioning rises, the implementation of high-efficiency condensate pumps can contribute to overall operational efficiency. This aligns with the ongoing research into optimizing energy use in cooling and dehumidification systems, bridging the gap between environmental responsibility and performance optimization in modern air conditioning solutions.

Troubleshooting Techniques for Common Condensate Pump Problems

When troubleshooting issues with air conditioner condensate pumps, it’s crucial to first understand the common problems these devices encounter. An excessive buildup of water can lead to pump failure, often due to clogs in the drain line or a faulty float switch. Checking for blockages and ensuring the float switch is operating properly are vital steps before considering any major repairs. Regular maintenance, such as cleaning the pump and inspecting the lines, can prevent many of these issues from arising.

Another common challenge is unusual noises during operation, which can indicate a mechanical failure or that the pump is working harder than it should due to improper installation. Verifying that the pump is level and securely mounted can often resolve these noise issues. Additionally, ensuring that the pump is adequately sized for the air conditioning system is essential for efficient operation. If problems persist, consulting a professional can provide specialized insights and solutions to restore optimal functionality to your condensate pump system.

Common Challenges Encountered with Air Conditioner Condensate Pumps and Their Solutions

| Issue |

Symptoms |

Cause |

Solution |

| Pump not starting |

No sound from the pump |

Power supply issues or faulty float switch |

Check power supply and inspect or replace the float switch |

| Leakage around the pump |

Water pooling near the pump |

Worn seals or loose fittings |

Replace seals and tighten fittings |

| Pump runs continuously |

Pump does not stop running |

Malfunctioning float mechanism |

Inspect and clean the float mechanism or replace it |

| Pump is noisy |

Unusual sounds during operation |

Debris in the pump or wear and tear |

Clean or remove debris and check for wear; lubricate or replace as needed |

| Clogged drain line |

Water backing up in the drain |

Debris buildup in the drain line |

Clear the drain line using a wet/dry vacuum or plumber's snake |

Cost Analysis: Maintenance vs. Replacement of Condensate Pumps

When considering the cost analysis of maintaining versus replacing air conditioner condensate pumps, it's essential to evaluate both short-term and long-term financial implications. According to the U.S. Department of Energy, the average lifespan of a condensate pump is around 5 to 10 years, depending on usage and maintenance. Routine maintenance can extend this lifespan and reduce the need for premature replacement. Basic upkeep, including regular checks for clogs and cleaning the pump components, costs approximately $100 to $200 annually.

On the other hand, if a pump fails and requires replacement, the costs can escalate significantly. The average price for a new condensate pump ranges from $150 to $300, excluding installation fees, which can add another $100 to $200. Data from the Air Conditioning Contractors of America suggests that ignoring regular maintenance could lead to more frequent replacements, potentially doubling costs over time. Therefore, investing in preventive maintenance not only enhances the pump's efficiency but also offers substantial savings and extends the pump's operational life, making it the more cost-effective choice in the long run.

Home

About Us

Products

Terminal Power Distribution Electric

AC Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06H-125 MCB 10-15KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY06-125 MCB 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05H-40 MCB Single Modular 6KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY05-32 MCB Single Modular 3KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY04-63 MCB 6-10KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03H-63 MCB 6KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY03-63 MCB 4.5KA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY02-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

BY01-63 MCB 3kA Miniature Circuit Breaker

MCB Accessories

Main Switch

RCBO RCCB

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY07L-63 RCCB 6KA Residual Current Circuit Breaker

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05HL-40 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY05L-32 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY04L-63 RCBO 6KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY03L-63 RCBO 4.5KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY02L-63 RCBO 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

BY01L-63 RCBO 1P+N 3KA Residual Current Circuit Breaker with Over-current Protection

Resettable Overvoltage and Undervoltage Protector

AC Contactor

AC Surge Protective Device

Changeover Switch

Photovoltaic System Protection

DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06H-125DC MCB 10-15kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY06-125DC MCB 6kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY04-63DC MCB 6-10kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03H-63DC MCB 6kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY03-63DC MCB 4.5kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY02-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

BY01-63DC MCB 3kA DC Miniature Circuit Breaker

RCD

DC Surge Protective Device

DC Fuse

PV Isolator Switch

PV Connector

Cable Gland

PV Cable

PV Knife Switch

DC Molded Case Circuit Breaker

Industrial Power Distribution Electric

Distribution Box

Air Conditioning System

Definite Purpose Magnetic Contactor

Condensate Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5018 1.8M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-5050 5M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

BY-11 1.2M Engineering Drainage Pump

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

SBH-05 0.7M Original Drainage Pump of Duct Type Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-24A/40A 10M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-50A 12M Drainage Pump of Air Conditioner

BY-24B/40B 10M Split Type Drainage Pump

BY-24B/40B 10M Split Type Drainage Pump

BY-100L 2M Drainage Pump of Air Conditioner

BY-100L 2M Drainage Pump of Air Conditioner

BY-360L 6M Large Displacement Drainage Pump

BY-360L 6M Large Displacement Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

BY-24C/40C 10M Corner Drainage Pump

News

Top Blog

Company News

Industry Dynamics

What is a miniature circuit breaker (MCB)?

PG Series Waterproof Cable Glands with Washer for Harsh Environments

LWSF-125 125A Manual Changeover Switch ensures reliable power transfer

BYX2 AC contactor series: reliable power control for modern electrical systems

High-performance 1000V DC fuse holder optimizes solar photovoltaic system protection

BY07L-63 Residual Current Circuit Breaker Ensures Global Electrical Safety

BYQ5 ATS Isolation Dual Power Automatic Transfer Switch

BY19G 63A Manual Changeover Switch: Features and Benefits

Support

Blog

Contact Us

OF SD MX OF MCB Miniature Circuit Breaker Accessories

OF SD MX OF MCB Miniature Circuit Breaker Accessories BYG1-125 Main Switch MCB Isolator Switch

BYG1-125 Main Switch MCB Isolator Switch BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector

BYVP1-63 100A Single Display Overvoltage and Undervoltage Protector BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector

BYVP2-63 40A 63A Adjustable Dual Display Overvoltage and Undervoltage Protector BYX2 6-95A AC Contactor

BYX2 6-95A AC Contactor BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device

BY08 1+2-7 SPD Class T1+T2 Imax 50KA Surge Protective Device BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device

BY08 1+2-12.5 SPD Class T1+T2 Imax 60KA Surge Protective Device BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device

BY08II-40 SPD Class T2 Imax 40KA Surge Protective Device BY19G 63A Manual Changeover Switch

BY19G 63A Manual Changeover Switch LWSF-125 125A Manual Changeover Switch

LWSF-125 125A Manual Changeover Switch BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device

BYF-63 RCD 10KA Type B AC+A+Smoothing DC Residual Current Device BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device

BY08DC 1+2-12.5 SPD Class T1+T2 40KA DC Surge Protective Device BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device

BY08IIDC-40 SPD Class T2 40KA DC Surge Protective Device BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link

BYPV-63 1500VDC 50A Fuse Holder with 10x85mm 14x85mm Fuse Link BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link

BYPV-30 1000VDC 32A Fuse Holder with 10x38mm Fuse Link BYPV-ELR2 PV Isolator Switch with Enclosed Version

BYPV-ELR2 PV Isolator Switch with Enclosed Version BYPV-ELR1 PV Isolator Switch with Enclosed Version

BYPV-ELR1 PV Isolator Switch with Enclosed Version BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle

BYPV-NL1/T PV Isolator Switch with Ultra-thin Lever Handle BYPV-NL1 PV Isolator Switch with Lever Handle

BYPV-NL1 PV Isolator Switch with Lever Handle BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle

BYPV-L1/L2 PV Isolator Switch with Lockable Lever Handle PV-BY-01 30A/50A 1000V Photovoltaic Connector

PV-BY-01 30A/50A 1000V Photovoltaic Connector PV-BY-02 30A/50A 1500V Photovoltaic Connector

PV-BY-02 30A/50A 1500V Photovoltaic Connector PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector

PV-BY-03 30A/50A 1000V Panel Mount Photovoltaic Connector PV-BY-F01 30A 1500V Diode/Fuse Type Connector

PV-BY-F01 30A 1500V Diode/Fuse Type Connector PV-BY-T 50A 1500V T Type Branch Connector

PV-BY-T 50A 1500V T Type Branch Connector PV-BY-Y 30A 1500V Y Type Branch Connector

PV-BY-Y 30A 1500V Y Type Branch Connector PG Waterproof Cable Gland with Washer

PG Waterproof Cable Gland with Washer Photovoltaic Cable

Photovoltaic Cable HD11N Photovoltaic Knife Switch

HD11N Photovoltaic Knife Switch BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker

BYM3DC MCCB Photovoltaic DC Molded Case Circuit Breaker BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker

BYM1DC MCCB 1000VDC Thermal Magnetic Type DC Molded Case Circuit Breaker BYM1E MCCB Electronic Type Molded Case Circuit Breaker

BYM1E MCCB Electronic Type Molded Case Circuit Breaker BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker

BYM1 MCCB Thermal Magnetic AC Molded Case Circuit Breaker BYW1 ACB Intelligent Universal Air Circuit Breaker

BYW1 ACB Intelligent Universal Air Circuit Breaker BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch

BYQ1 ATS Isolated Type PC Level Dual Power Automatic Transfer Switch BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Intelligent Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS End Type CB Level Dual Power Automatic Transfer Switch BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch

BYQ1 ATS Mini Type CB Level Dual Power Automatic Transfer Switch Stainless Steel Hinge Type Electrical Box

Stainless Steel Hinge Type Electrical Box HA Waterproof Distribution Box

HA Waterproof Distribution Box HT Waterproof Distribution Box

HT Waterproof Distribution Box BS Definite Purpose Magnetic AC Contactor

BS Definite Purpose Magnetic AC Contactor